Electric Cylinder LAMBDA

Economic electric cylinder with high force

The Lambda is a compact powerhouse. It combines compact installation dimensions with an enormous thrust force of up to 6,000 N. It is designed for use under extreme conditions. Not wetness, vibrations, dirt, cold nor heat can throw it off its stride. Its modular design enables it to be adapted to a wide range of applications.

Safety functions of LAMBDA to protect the user

Since the Lambda was originally designed for hospital beds, it comes with special safety features:

- Pinch protection (optional)

- Manual disengagement and current-free adjustment using a Bowden cable (optional)

- Passive safety due to high self-locking

- Limit switch

Customer benefits

| Robust construction | |

| Protection class IP66 | |

| Integrated hall sensor | |

| Motor thermal protection | |

| Individually adjustable, stepless stroke length | |

| Adjustable load up to max. 6.000 N | |

| Easy integration into existing systems |

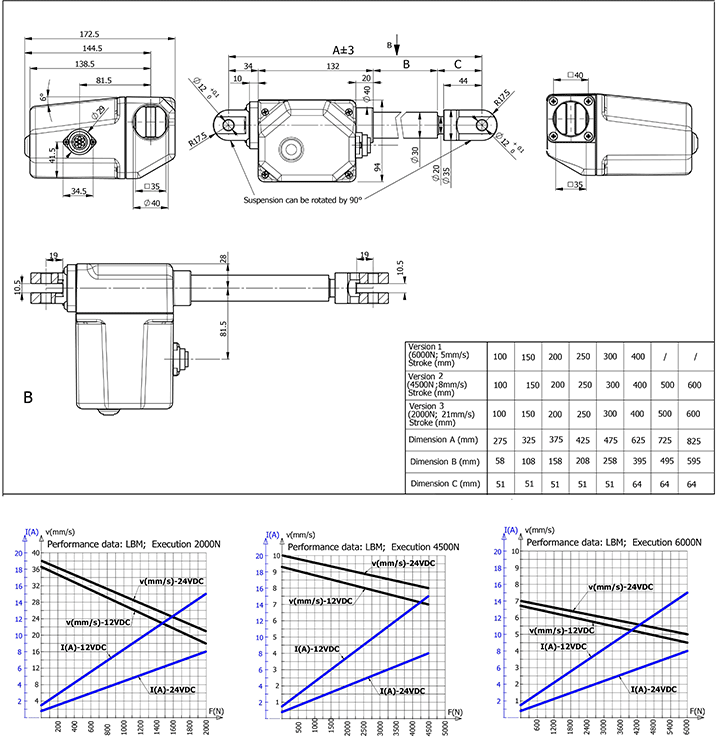

Standard configurations

General Data |

|

|---|---|

Force |

max. 6000N |

Speed |

max. 38mm/s |

Stroke length |

min. 15mm - max. 600mm |

Installation dimension (B) |

smaller than stroke 400mm = stroke +175mm greater or eaqual than stroke 400mm = stroke +225mm |

Duty cycle |

10% / 20min (AB 2/18) |

Position feedback |

optional |

Synchronous operation |

yes with control unite |

Supply voltage |

12VDC or 24VDC |

Intergrated limit switch |

yes |

End position signal |

optional |

Protection class |

IP66 (static) |

Self-locking |

up to nominal load |

Ambient temperature range |

-20°C to +60°C |

Components |

|

Rod end |

POM, hole 12.1mm |

Housing end |

POM, hole 12.1mm |

Lift tube material |

Stainless steel |

Housing material |

POM |

Housing colour |

black |

Connection |

Connector Amphenol 6-pole or Hrischmann GDM |

Cable length |

1,5m , 3m |

Options |

|

| Suspensions individually selectable Special strokes adjustable ex works |

More data

Control / Regulation |

Voltage polarity |

Position feedback |

End position feedback potential bound End position feedback potential-free Potentiometer |

Monitoring |

Thermoswitch |

A modular design ensures versatility

This linear drive is available in various versions so it is suitable for a wide range of applications:

- Stroke length: Standard stroke lengths from 100 mm to 600 mm. We can also supply you with special stroke lengths or special installation lengths on request.

- Gearing: Choose between three versions. From 6,000 N at 5 mm/s to 2,000 N at 21 mm/s.

- Safety: In addition to the standard version without anti-pinch protection, the Lambda is available with anti-pinch protection on pulling or pushing.

- Hanging mechanisms can be selected as needed. We can also customize the adapters and couplings individually to fit your requirements. Just ask us!

- Housing: Customized paints, special colours and special installation dimensions – everything is possible.

- Operating voltage: You can choose either 24 VDC or 12 VDC.

- Position feedback: optional analogue position feedback with potentiometer

- Electrical connection options: Apart from the standard version with the 2-pole plug, the Lambda is also available with a cable connection and with an integrated potentiometer. Other connections – such as potential-linked (non-isolated) or potential-free signal contacts or signal contacts for intermediate stroke positions – are also available on request.

- Cable length and plug: The cable length and connections / plugs can be customized on request.

High quality and resistant

The electric cylinder has a robust resistant housing made of plastic, with a stable casing made of an anodized aluminium profile and a lift pipe made of stainless steel. Inside, there is a maintenance-free DC motor that features enormous reliability and longevity. The housing and hanging mechanism are manufactured with the greatest care and precision.

Thanks to its high IP66 protection class (static), the housing can even withstand a strong water jet without any problems.

Even under extreme environmental conditions, the linear drive is reliable and trouble-free. It tolerates ambient temperatures of -10 to 60 degrees Celsius and is insensitive to UV radiation from the sun.

This linear drive is also popular in the offshore sector (e.g. for ocean-going yachts or cruise ships). Years of operation while in contact with seawater and salt spray do not affect its reliable functionality. Likewise, the violent vibrations of off-highway machines cannot harm it.

Typical applications for the LAMBDA electric cylinder

Because it is so robust, the Lambda is often used in harsh industrial environments and in outdoor applications. It is suitable for use in agricultural machines, off-highway vehicles, municipal machines and in the offshore sector – in other words, wherever the electric cylinder must function precisely and reliably under harsh environmental conditions. Here are some typical examples of Lambda usage:

Agricultural machinery:

- Moving flaps

Mobile and off-highway:

- Opening and closing the service openings on aircraft

- Regulation of shading and fresh air supply for passenger bridges at airports

Marine technology:

- Opening and closing of dinghy/tender garages

- Moving the bathing platforms

Industrial and logistics

- Format adjustments on conveyor belts and production facilities

- Fresh air regulation

- Opening and closing the lids in industrial kitchens