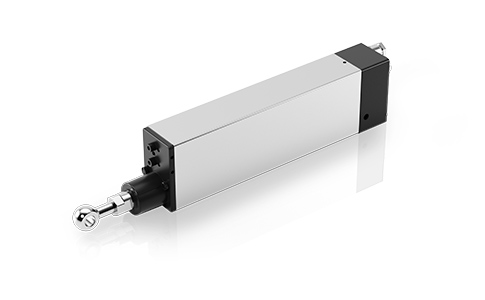

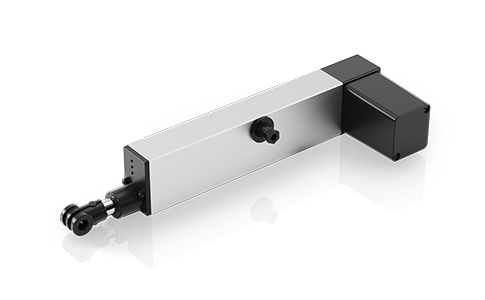

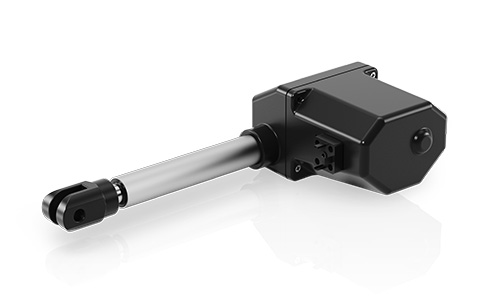

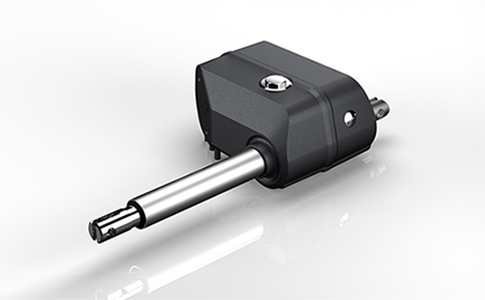

Linear actuators with outstanding environmental stability

Drives are exposed to extreme conditions during usage in agriculture, off-highway and industrial applications. Not every device can withstand heat, dust, cold and vibrations – but linear drives from Phoenix Mecano can because they meet these requirements. Find out why here.

How does a linear actuator work?

A linear actuator converts a rotary movement into a linear movement. An electric motor moves a lifting rod that moves back and forth depending on the direction of rotation.

The conversion of movement takes place in a gearbox. Depending on the transmission ratio of the gearbox, the lifting rod is moved with more force, but slower, or with less force, but faster. Our linear actuators provide several variants of gear ratios which are available for all models. Thus, the actuator can be matched exactly to the requirements of the application.

The travel movement of the lifting rod is limited by electrical limit switches. Depending on the model, the limit switch can be adjusted from the outside, allowing shorter stroke lengths.

Certain models also offer automatic blocking switch-off and temperature monitoring features. Overcurrent protection prevents damage to the electric motor that could be caused by excessive currents.

Our electric cylinders operate using direct current – usually 12, 24 or 48 volts. The rotary movement and the corresponding direction of movement of the lifting rod are controlled by polarity reversal. Handsets or electronic controls can be used for this purpose.

The advantages of linear actuators

Electric cylinders are increasingly replacing pneumatic and hydraulic systems. And that is because linear actuators have many important advantages:

- Slim construction: No compressors, valves or hoses are necessary. Only thin cables.

- Clean: In contrast to hydraulic cylinders, electric cylinders do not work with oil. There are no annoying leaks that contaminate the machine.

- Quiet: Linear actuators are quiet and do not disturb.

- Efficient: Compared to combustion engines and compressors, electric cylinders have a much higher efficiency. There is hardly any energy wasted in the form of heat radiation.

- Configurable movements: Models with integrated digital controllers enable the movements and acceleration to be adjusted individually.

- Precision: The movements are executed with pinpoint accuracy and repeatable precision.

- Position feedback: Linear actuators can report their exact positions back to the controller. Accurate to the millimetre.

The most important advantage of electric cylinders is their electronic communications. They can be controlled by an electronic system and can transmit information to it. This makes them a key tool for the digitalization of machines, vehicles and building controls.

Why a linear actuator from Phoenix Mecano?

Phoenix Mecano is a manufacturer for linear actuators specifically designed for use under extreme conditions. One of their core features is their robustness and durability. The compact linear dives not only offer high operational reliability in extreme climatic conditions (hot/cold) while they can also withstand UV radiation in the open field for several years without any issues. In addition, the devices have a high degree of protection -The linear actuators LD1000 and LD75, for example, up to protection class IP69k. This means they are protected against dust and water, even under heavy pressure on the housing. The maintenance-free DC motors used (12V, 24V and 48V) ensure the high reliability of our drive systems.

Another reason for choosing Phoenix Mecano is that we can offer individually customised linear actuators tailored to your specific needs starting from a single piece. Our LEAN production enables us to manufacture any desired stroke length within the mechanical possibilities of the respective electric cylinder. In most cases, this reduces the built-in dimension and thus saves valuable installation space. The compact design also facilitates installation in existing systems and machines. Of course, all other components such as cable length, connectors, receptacles, color, etc. can also be customized to your needs and specifications.

Phoenix Mecano also offers electric cylinders as plug and play system solutions. In this case, you receive a package comprising of the cylinder with operating unit and a control system configured to your requirements. True to the motto: "Unpack, install and get started".

Controller and communication

Models with integrated electronic controllers – such as our LD1000C – can not only control the direction of movement of the linear actuator. They also feature additional control options:

- Speed regulating

- Configurable speed

- Programmable start/stop ramps

Position feedback signals are important for integrating the linear actuators into controllers or systems. There are a many variants here:

- End position feedback as potential-free or potential-linked

- Potentiometer (analogue position feedback)

- Hall sensor (absolute displacement measuring system)

- Digital position signal query (via integrated control electronics)

An interesting capability that linear drives with integrated electronic control offer is synchronous movements. This involves moving up to four linear actuators synchronously. One of the actuators is controlled and the other three automatically move in step with it. What is interesting here is that any shifts in the positions among the synchronous drives – for example due to mechanical action – can be compensated automatically because each linear actuator can "report" its exact position digitally.

Robustness of the linear drives

Linear actuators from Phoenix Mecano are specially designed to be used in extreme conditions:

- Dust and vibrations in off-highway vehicles, including construction machinery

- Water and salt spray in the offshore sector

- Wet conditions and even direct water jets

- Impact and pressure on the housing

- Extreme temperatures

In summary, robustness and durability are the key features of Phoenix Mecano's linear drives. These compact actuators not only offer high operational reliability in extreme heat up to over 60° C and icy cold down to -20° C, they can also withstand UV radiation in the open air for several years without any problems.

The electrics cylinders also feature a high protection class. The LD1000 and LD75 linear actuators, for example, provide up to protection class IP69k, which guarantees resistance even to a direct jet from a high-pressure cleaner.

Quality features of our linear actuators

Product quality is very important for Phoenix Mecano. All electric cylinders have the same quality features – ensuring durability and a favourable Total Cost of Ownership (TOC):

- Mature designs that have been proven in countless applications

- Maintenance-free high-quality motors

- Stainless precision gears

- Stainless steel stroke pipes

- High-quality housing made of aluminium or robust POM

We use tough tests to ensure that our linear actuators can perfectly meet the specified requirements. The most important tests include:

- Stress test: An endurance test under the influence of vibration, dust and maximum mechanical load.

- Robustness test: Testing for heat, cold, salt water resistance and IP69k extreme test.

- Electronics testing: Detailed test of the electronic parameters and functionality of the drive.

Linear actuator "Customized" is for us standard

Our philosophy: The linear actuator should adapt to the design, and not vice versa. That is why we place great emphasis on compact, versatile configurable models:

- A variety of gear ratios

- Adjustable stroke lengths

- Various hanging variants

- Multiple housing versions

- Different operating voltages

- Position feedback options

What other manufacturers consider a "special design" is for us standard! Since we produce the actuators ourselves, we can also modify them as desired. In addition to customized stroke lengths, housing shapes, housing surfaces and bore holes, we also offer special cable length configurations, connectors and receptacles. Tell us your requirements and we will manufacture a linear actuator that is precisely tailored to your needs.

Thus, you receive a drive that fits ideally into your design: compact, unobtrusive, easy to maintain, and with the right adjustment force and speed.

Thanks to our LEAN production, we are able to produce even the smallest batch sizes economically, and many times faster than other suppliers of linear drives.

The applications for our linear actuators

Our linear actuators are used wherever robustness, reliability and flexible installation options are required.

Agricultural machinery

The digitalization of agriculture (automation, precision farming) opens up a wide range of applications for electric cylinders. This includes:

- Combine harvesters: Adjustment of the various threshing components, reel adjustment, adjustment of the discharge hopper and the grain sieve

- Fertilizer spreaders: Adjustment of the spread pattern and dosage

- Balers: Precise tightening of the net, net cutter regulation

- Cultivation technology: Seed dosage, raising/lowering the bout marker on seed drills

Mobile and off-highway vehicles

Construction machinery, transport vehicles, baggage conveyor carts, fire and rescue vehicles and lifting systems all have one thing in common: They require robust, intelligently controlled actuators. Typical applications for our linear actuators include:

- Municipal vehicles: Adjustment of attachments such as ladders or equipment at the push of a button

- Baggage conveyor machines: Fast, precise adjustment for docking the conveyor to the loading vehicle

- Construction machinery: Retrofitting for functions such as automatic idle cut-off, hydraulic replacement, etc.

- Lifting systems: Fine adjustment of support mechanisms, support arms, etc. with precise digital position feedback

Industrial and logistics

Linear actuators are an integral component for the automation and digitalization of industrial machines, vehicles, lifting and lowering equipment and building fixtures. Here are some applications at a logistics centre to demonstrate this:

- Controlling shading systems

- Controlling the supply of fresh air

- Controlling loading ramps

- Adjusting of access/loading ramps

- Opening and closing the exhaust air hatches

- Controlling the building ventilation system

- Opening and closing windows

- Lifting and lowering functions for transport racks

- Coupling systems for industrial trucks

Offshore and marine technology

The wide range of applications for our linear actuators extends from sailing yachts to container ships, and from assembly equipment to processing plants. On an ocean-going yacht, for example, electric cylinders are found in the following places:

- Controlling bathing platforms

- Opening and closing all types of windows and hatches

- Adjusting the helmsman's seat

- Setting the GPS antenna

- Various lifting and lowering devices

- Remote control of devices

- Electric controls for sailboats (e.g. for centreboard or sails)

What are YOU working on? Get in touch with us. Together, we'll find the most efficient, durable and convincing drive solution for your construction requirements.